TM 5-6115-332-14

P-8-614-14

TO 35C2-3-424-1

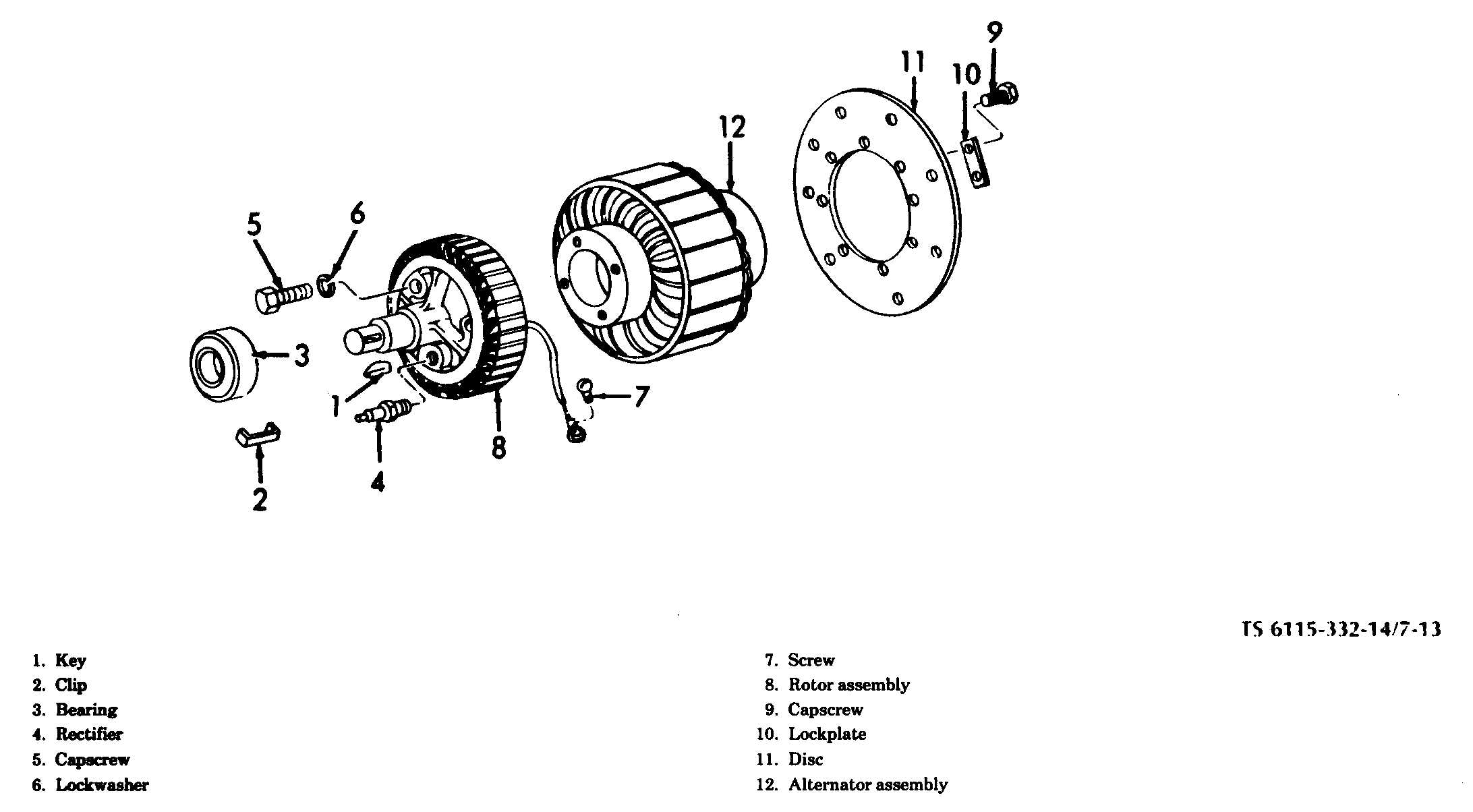

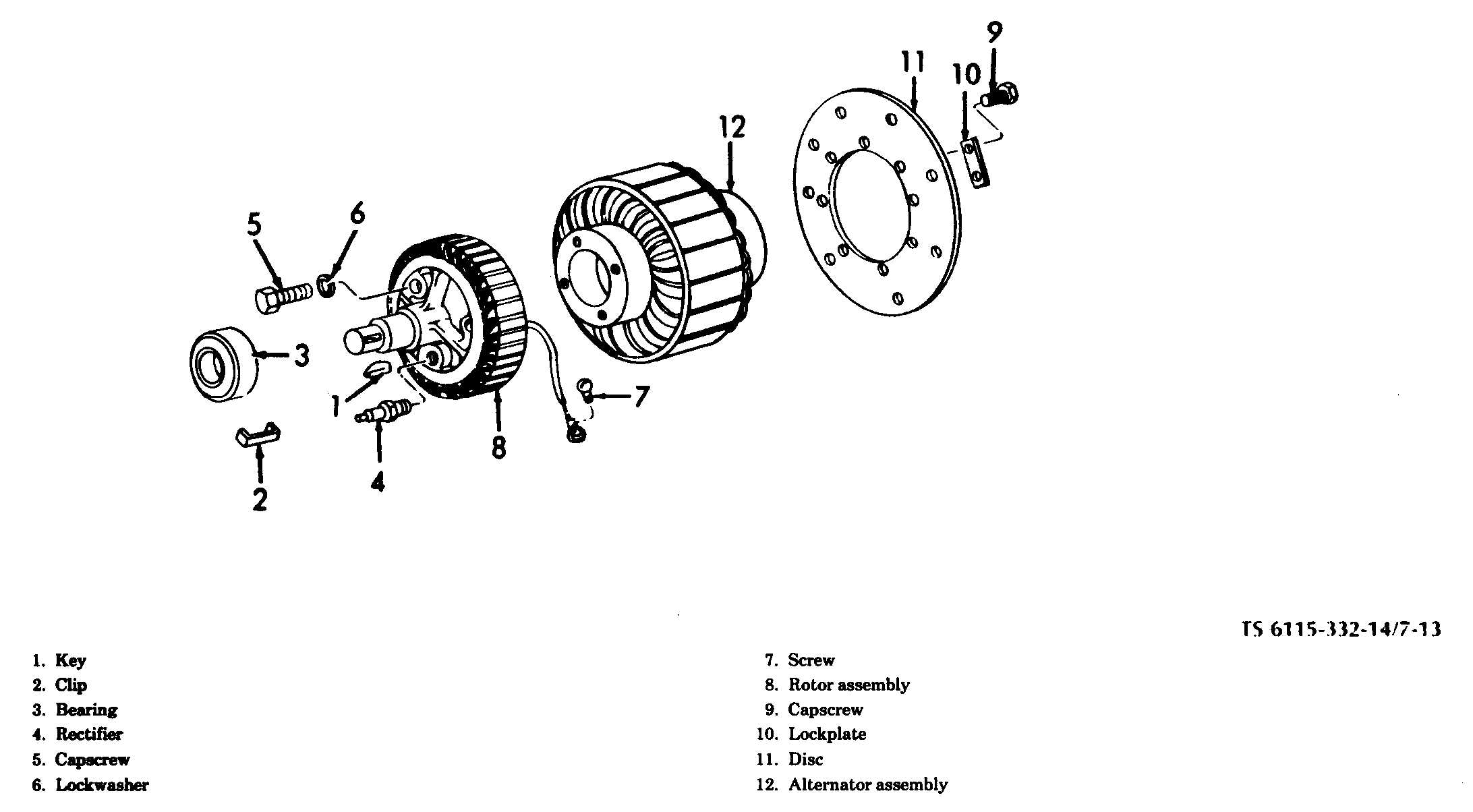

Figure 7-13. Main generator rotor assembly, disassembly (Model MEP-022A).

Cleaning.

Clean all parts in a well-ventilated area.

Avoid inhalation of solvent fumes and

prolonged exposure of skin to cleaning

solvent. Wash exposed skin thoroughly.

Dry cleaning solvent (Fed. Spec. P-D-680,

Type II) used to clean parts is potentially

dangerous to personnel and property. Do

not use near open flame or excessive heat.

Flash point of solvent is 140°F (60 °C).

(1) Clean items with cleaning solvent, Fed.

Spec. P-D-680 Type II, and dry thoroughly.

d. Inspection.

(1) Inspect the fan, drive disk, and disk

adapter for cracks and defective threads.

(2) Rotate the bearing to check for binding

and roughness. Inspect the seal and retaining clip.

(3) Inspect the rotor shaft for nicks, rust,

wear, damage to the keyway, and defective internal

threads on the end of the shaft.

(4) Inspect the windings and leads for evi-

dence of overheating, deterioration of the varnish,

and other damage.

(5) Inspect the rotating rectifier for broken

connections and damaged diodes.

e. Repair.

(1) Replace a defective rotor assembly or com-

ponent.

(2) A reusable bearing shall be carefully re-

moved from the shaft by applying pressure to the

inner race, only. A defective bearing shall be re-

placed.

(3) If any windings must be replaced or if im-

balance is detected, balance the rotor assembly to

within a value of 0.5 ounce inches.

(4) Refer to paragraph 7-13e (2) for baking

data and to figures 7-14 and 7-15 for winding data.

Change 5

7-21