TM 5-6115-332-14

P-8-614-14

TO 35C2-3-424-1

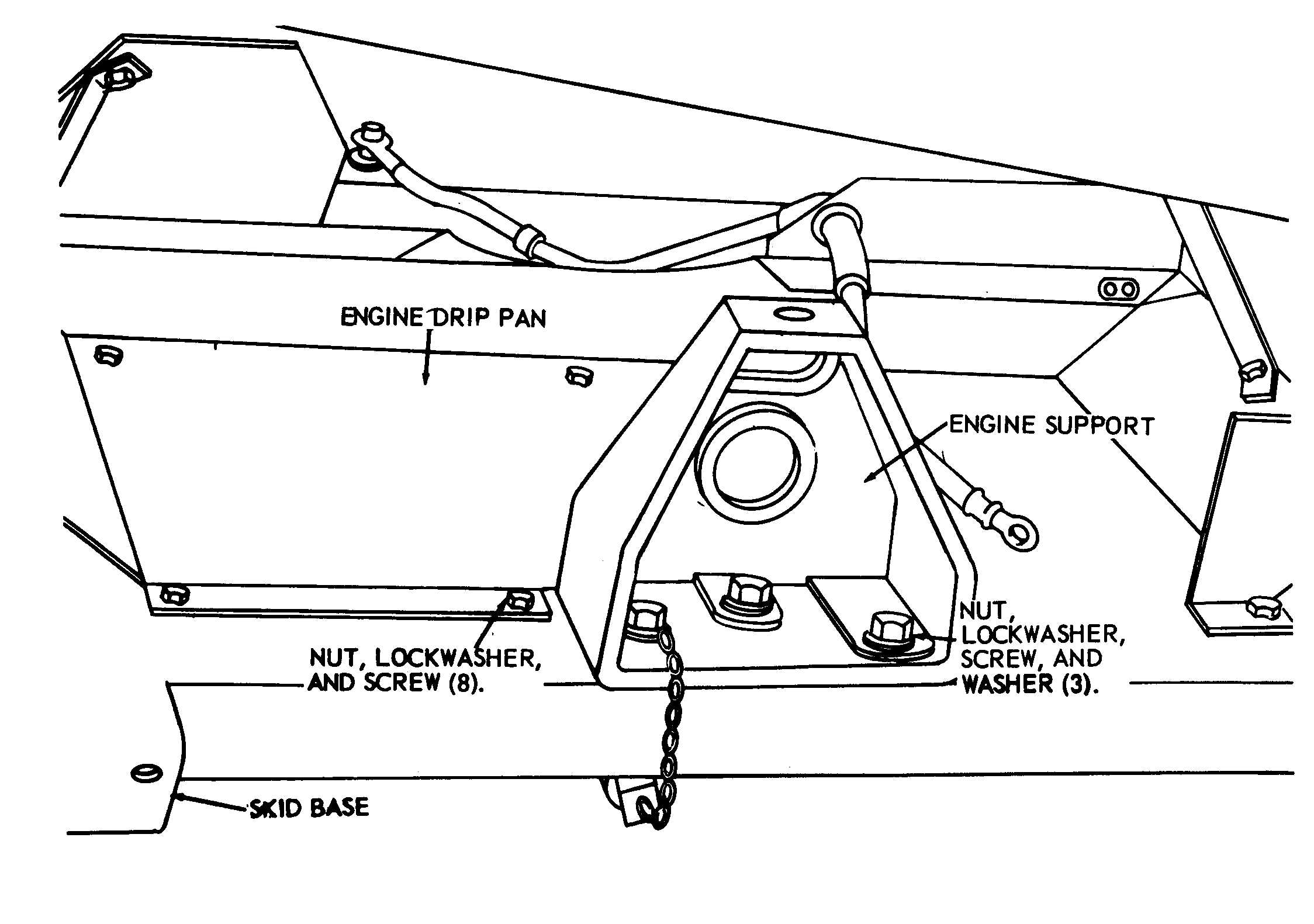

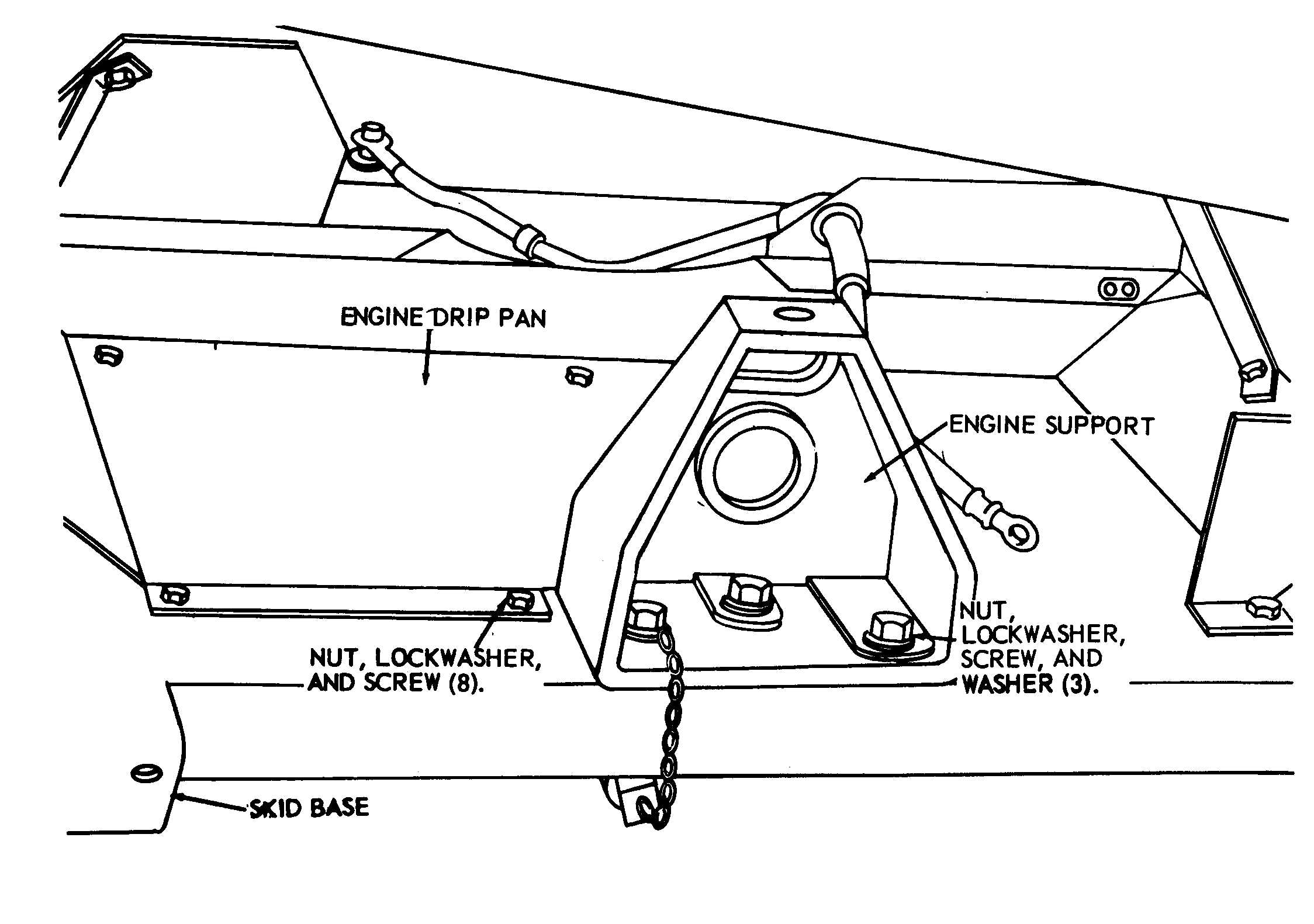

F i g u r e 7 - 1 6 . E n g i n e S u p p o r t a n d d r i p p a n , r e m o v a l a n d i n s t a l l a t i o n .

b. Cleaning, Inspection and Repair.

Clean all parts in a well-ventilated area.

Avoid inhalation of solvent fumes and

prolonged exposure of skin to cleaning

solvent. Wash exposed skin thoroughly.

Dry cleaning solvent (Fed. Spec. P-D-680,

Type II) used to clean parts is potentially

dangerous to personnel and property. Do

not use near open flame or excessive heat.

Flash point of solvent is 140 “F (60 ‘C).

(1) Clean items with cleaning solvent, Fed.

Spec. P-D-680 Type II, and dry thoroughly.

(2) Inspect the drip pan for cracks, dents, and

distortion. Straighten distorted or dented areas.

Weld cracks and grind the welds’ smooth.

(3) Inspect the engine support for cracks and

other damage.

(4) Replace defective parts.

c. Installation.

(1) Secure the drip pan to the skid base with

screws, lockwashers and nuts.

(2) Position the engine support in place on the

skid base.

(3) Secure with flatwashers, screws, lock-

washers and nuts.

(4) Install the engine (para 6-4).

7-17. Skid Base

a. Removal.

(1) Remove the engine, paragraph 6-4, and

generator, paragraph 6-2 or 6-3.

(2) Remove the engine support and drip pan,

Change 5

7-25