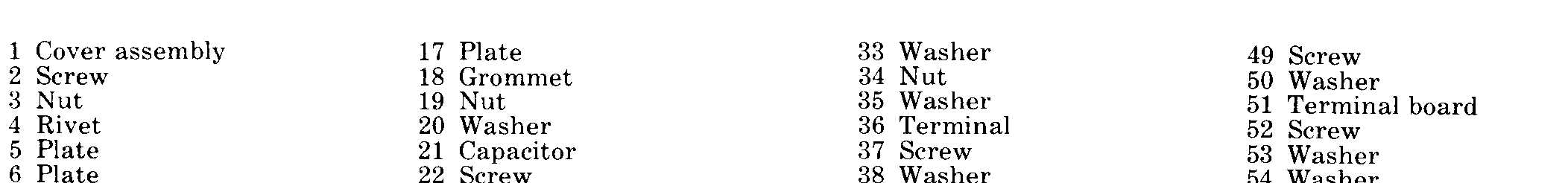

Figure 8-1-Continued.

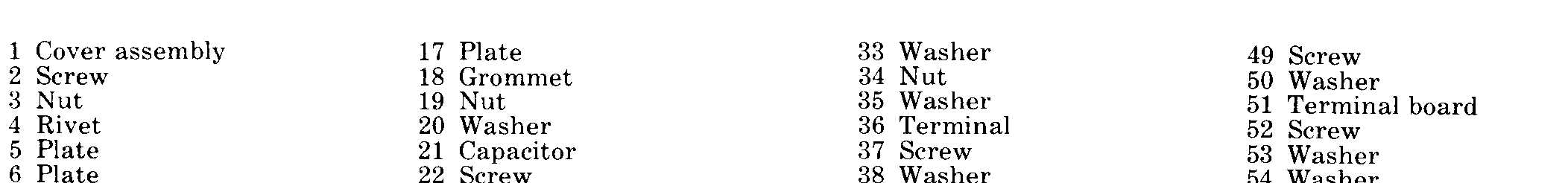

Figure 8-1

TM 5–6115-323-14

the regulator terminals, the voltage regulator is

defective and should be replaced.

(c) If voltage across regulator terminals 5

and 6 is satisfactory, stop the generator set, at-

tach the load cables, and restart the set.

(d) If voltage is still not satisfactory replace

the voltage regulator and repeat steps (a) thru (d).

(3) Transducer.

(a) Disconnect load cables and start genera-

tor set.

(b) With the multimeter, check output volt-

age across load terminals. Then check input volt-

age across terminals 3 and 4 of the transducer.

These readings should have about the same value

(120 V approximately).

(c) Check input voltage from variable resis-

tor across terminals 1 and 2 of transducer. This

reading will vary but should be approximately 20

v.

(d) Check transducer output to voltage reg-

ulator. Terminals 5 and 6 should be about 120 V.

Terminals 7 and 8 should be about 25 volts.

(e) If output voltages do not meet specifica-

tions, replace voltage transducer.

(4) Capacitor (noise suppression).

NOTE

The only accurate way to test a capacitor is by

putting it on a capacitor testor. However, you can

tell if a capacitor is working by the following

method.

(a) Stop the generator and disconnect the

lead-in terminal to the capacitor.

(b) With the multimeter on ohms setting,

touch test probes to input terminal and capacitor

metal case, then reverse the probes. The multime-

ter will give a momentary reading then fall back

to zero.

the

(c) If this reading does not occur, replace

capacitor.

(5) Frequency converter.

(a) Stop the generator set and disconnect

either the positive or negative lead from the

frequency converter output to the frequency me-

ter.

(b) Start the generator set and measure

input voltage across terminals L1 on the fre-

quency converter with a multimeter. This voltage

will normally be 120 volts AC.

(c) Observing polarity with the multimeter,

measure DC microampher current output on +

and – terminals at the converter. This microam-

pher DC should be within the 0 to 200 microam-

pher range, and at 120 volts, 60 Hz, during opera-

tion this reading should be close to 100 microam-

pher.

(d) If measurements do not meet specifica-

tions above, replace the frequency converter.

(6) Variable resistor (AC).

(a) Stop generator set and disconnect termi-

nal 5 of TB 1 (fig. 1-5).

(b) Insert multimeter probes to this discon-

nected wire and terminal 6 in TB 1 (fig. 1–5). With

the variable resistor in the full counterclockwise

position slowly turn the control knob to the full

clockwise position. This reading should move

smoothly from 0 to 1100 ohms A 20%, as the

variable resistor is rotated to the full clockwise

position.

(c) If the reading is not within specifica-

tions, replace the variable resistor.

8-3. Control Box (DC Unit)

a. Removal and Disassembly.

(1) Remove the control box (para 6-3).

(2) Refer to figure 8-2 and disassemble the

control box.

b. Cleaning and Inspection.

(1) Clean all parts thoroughly.

(2) Inspect all parts for signs of burning or

8–3