TM 5-6115-271-14

TO 35C2-3-386-1

TM-05926A-14

NAVFAC P-8-613-14

Table 5-1. Troubleshooting (Cont'd)

Table 5-1. Troubleshooting (Cont'd)

MALFUNCTION

MALFUNCTION

TEST OR INSPECTION

TEST OR INSPECTION

CORRECTIVE ACTION

CORRECTIVE ACTION

4. GENERATOR FREQUENCY FLUCTUATES

3. GENERATOR FAILS TO SUPPLY LOAD

(Cont'd)

OR DROPS UNDER LOAD (Models

MEP-016A/C and MEP-021A/C) (Cont'd)

Step 4. Test the circuit breaker as follows:

a. Attach a variable load to output ter-

b. The generator will shut down.

minals and start the generator set.

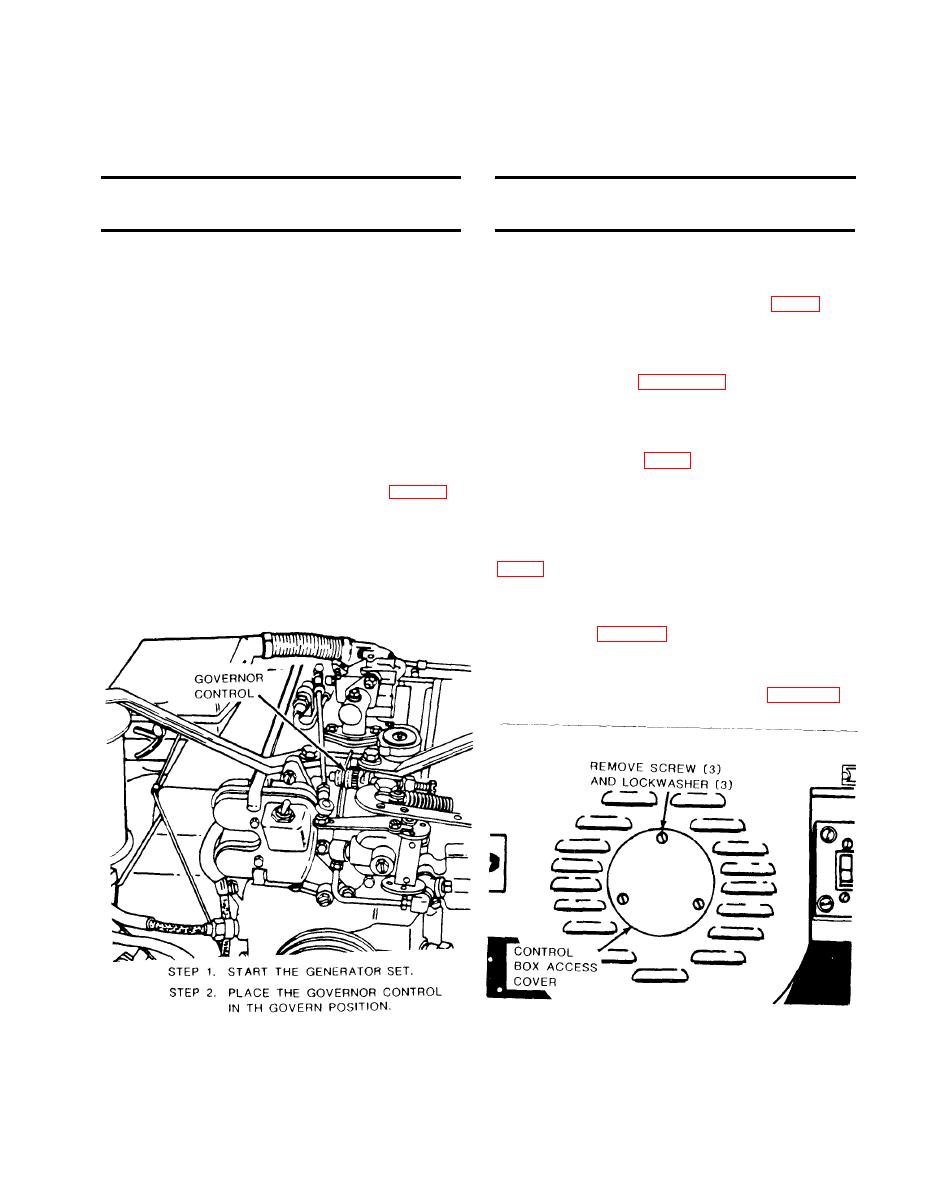

(1) Adjust the governor (fig. 5-1).

b. Move circuit breaker to ON position

(a) Start the generator.

and observe load meter and voltmeter.

(b) Place the governor control in

Reading at redline on load meter is 100%

the govern position.

load. Circuit breaker should stay on in-

(2) Refer to appropriate service

manual in Appendix A for other corrective

definitely under 100% load.

c. Adjust variable load until load meter

action.

reads in red portion of load meter. Circuit

Step 2. Check the engine for out of adjustment or

breaker should trip when indicator enters

defects. The frequency and load meters

red portion of load meter.

will fluctuate and then drop off.

Adjust (fig. 5-1) or replace the gover-

If circuit breaker trips below max-

nor (see appropriate service manual in Ap-

imum load (100% of 0.8 PF), (Power Fac-

tor), replace the circuit breaker (para 8-8).

pendix A).

5. GENERATOR NOISY

4. GENERATOR FREQUENCY FLUCTUATES

Inspect for a defective bearing.

OR DROPS UNDER LOAD (Models

a. On models manufactured prior to 1968, check

MEP-016A/C and MEP-021A/C)

the bearing by removing the control box access cover

Inspect the engine to see if it is lacking

Step 1.

power. Some indications are:

(1) Remove the three screws and lockwashers.

a. Generator will not achieve its rated

(2) Remove the control box access cover.

voltage.

(b) On models manufactured after 1968, tear down

the generator (para 10-2) and visually inspect the

bearing.

c. Examine the bearing for signs of wear or

discoloration.

Replace a defective bearing (para 10-2).

GENERAL MAINTENANCE

Section III.

The maintenance to be performed by intermediate (field), (direct support and general support) and depot

maintenance personnel on this equipment is limited to repair of the frame. Repair is accomplished by straighten-

ing bends using the furnished cutting and welding torch outfit or by replacement.