TM 5-6115-271-14

TO 35C2-3-386-1

TM 05926A-14

NAVFAC P-8-613-14

Section V. TROUBLESHOOTING

4-11. General

Table 4-2. Troubleshooting

This section contains troubleshooting or malfunction

information and tests for locating and correcting most

MALFUNCTION

of the troubles which may develop in the generator

TEST OR INSPECTION

CORRECTIVE ACTION

sets. Each malfunction or trouble symptom for an

individual component, unit, or system is followed by a

1. GENERATOR FAILS TO SUPPLY LOAD

list of tests or inspections necessary for you to

determine probable causes and suggested corrective

Step 1. Inspect the load terminals for cracks, breaks,

actions for you to remedy the malfunction.

loose terminals and other damage. Replace

4-12. Troubleshooting

receptacle on MEP-026A28VDC model;

a. This manual cannot list all possible malfunctions

Repair or replace as necessary.

that may occur or all tests or inspections, and

Step 2. Check the circuit breaker to see if it is open.

corrective actions. If a malfunction is not listed (except

Close the circuit breaker; if the circuit

when malfunction and cause are obvious), or is not

breaker will not stay closed, it is defective.

corrected by listed corrective actions, you should

Refer to intermediate (field), (Direct

notify higher level maintenance.

support and general support) maintenance

personnel.

may find during the operation or maintenance of the

generator sets or their components. You should

loose connections or breaks. If either of these

parts are defective, there will be no voltage

perform the tests/inspections and corrective actions in

registering on the voltmeter. Refer to

the order listed.

intermediate (field), (Direct support and

general support) maintenance personnel.

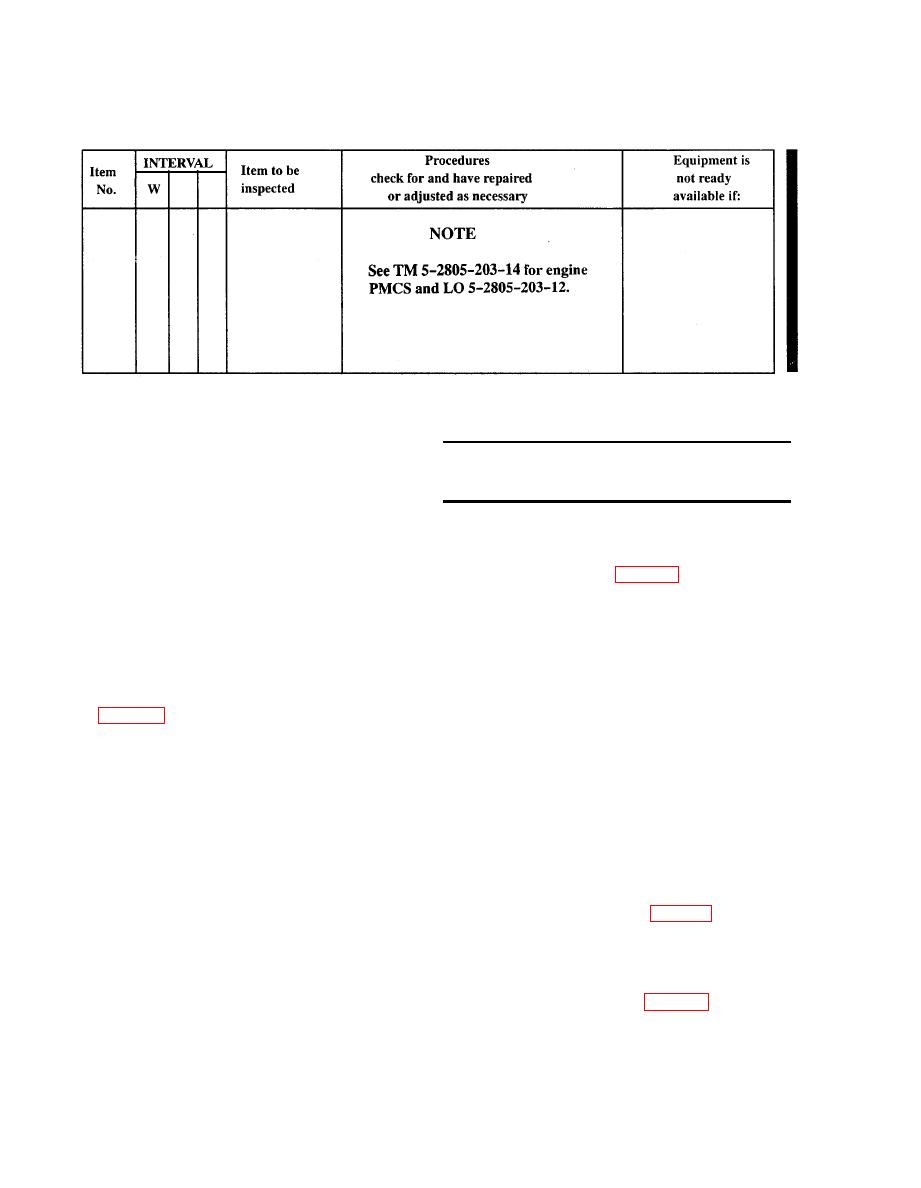

NOTE

Before you use this table, be sure you have

2. GENERATOR FAILS TO SUPPLY LOAD

performed all normal operational checks. If you

(Model MEP-016A)

have a malfunction which is not listed in this

Step 1. Inspect for a cracked, broken or corroded

table, notify the next higher level of

maintenance.

Replace the fuseholder (para 4-19).

Step 2. Test for a defective connector by plugging a

Air Force users may perform maintenance

known good test lamp into the receptacle. If

within the scope of their capabilities.

the test lamp fails to illuminate connector is

defective.

Replace the connector (para 4-23).

Change 12