TM 5-6115-596-14

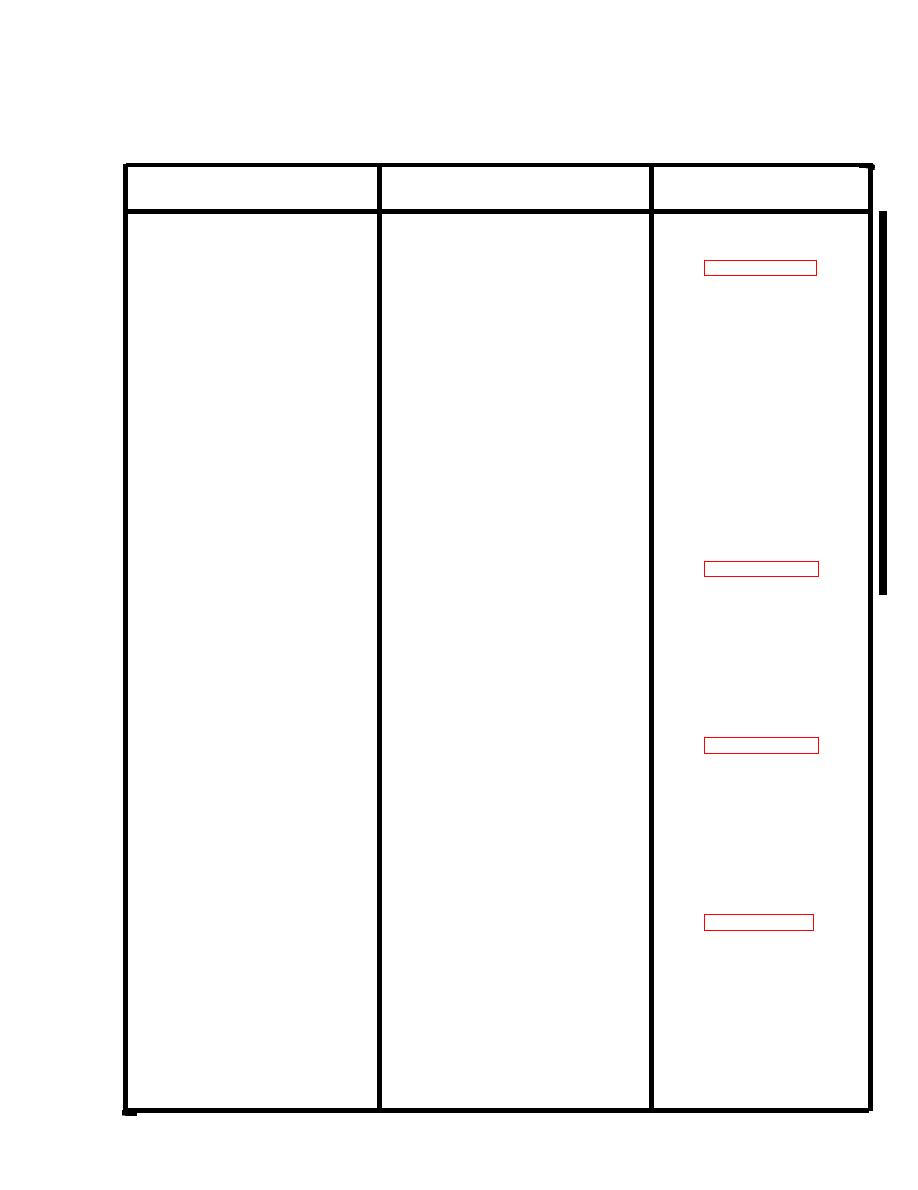

Table 5-3.

Direct and General Support Troubleshooting

(Continued)

Corrective Action

Probable causes (tests)

Malfunction (symptoms)

(remedies)

c. Check for defec-

c. Defective rheostat

5. Continued

tive rheostat

(generator sets

923-001 thru 923-

Replace defec-

553) .

tive rheostat

(4-27 through

4-30).

d. Replace brushes

d. Brushes making poor

if approaching

contact with com-

their minimum

mutator.

length (para.

5-22c). Seat

and run-in

brushes (para.

5-25) .

e. Replace arma-

e. Short-circuited

ture (para. 5-

armature.

25).

f. Replace housing

f. Short-circuited or

grounded field

windings.

a. Seat and run-in

a. Brushes not properly

7. Excessive sparking

brushes (para.

seated on commutator.

at brushes.

5-25).

b. Replace arma-

b. Open-circuited or

ture (para. 5-

short-circuited

20).

armature.

c. Replace housing

c. Short-circuited

field winding.

d. Resurface com-

d. Pitted or eccentric

mutator (para.

commutator.

5-23b).

e. Replace ball

e. Worn ball bearings.

bearings (para.

5-20).

a. Disassemble and

a. Obstruction in air

8. Generator overheats.

clean generator

passages.

and 5-21).

b. Replace cooling

b. Broken cooling fan.

fan (para. 5-

20).

c. Replace insula-

c. Grounded insulated

ted tube (para.

brush.

5-20).

d. Replace arma-

d. Open armature

ture (para. 5-

winding.

20).

Change 2 5-7