TM 5-6115-332-14

P-8-614-14

TO 35C2-3-424-1

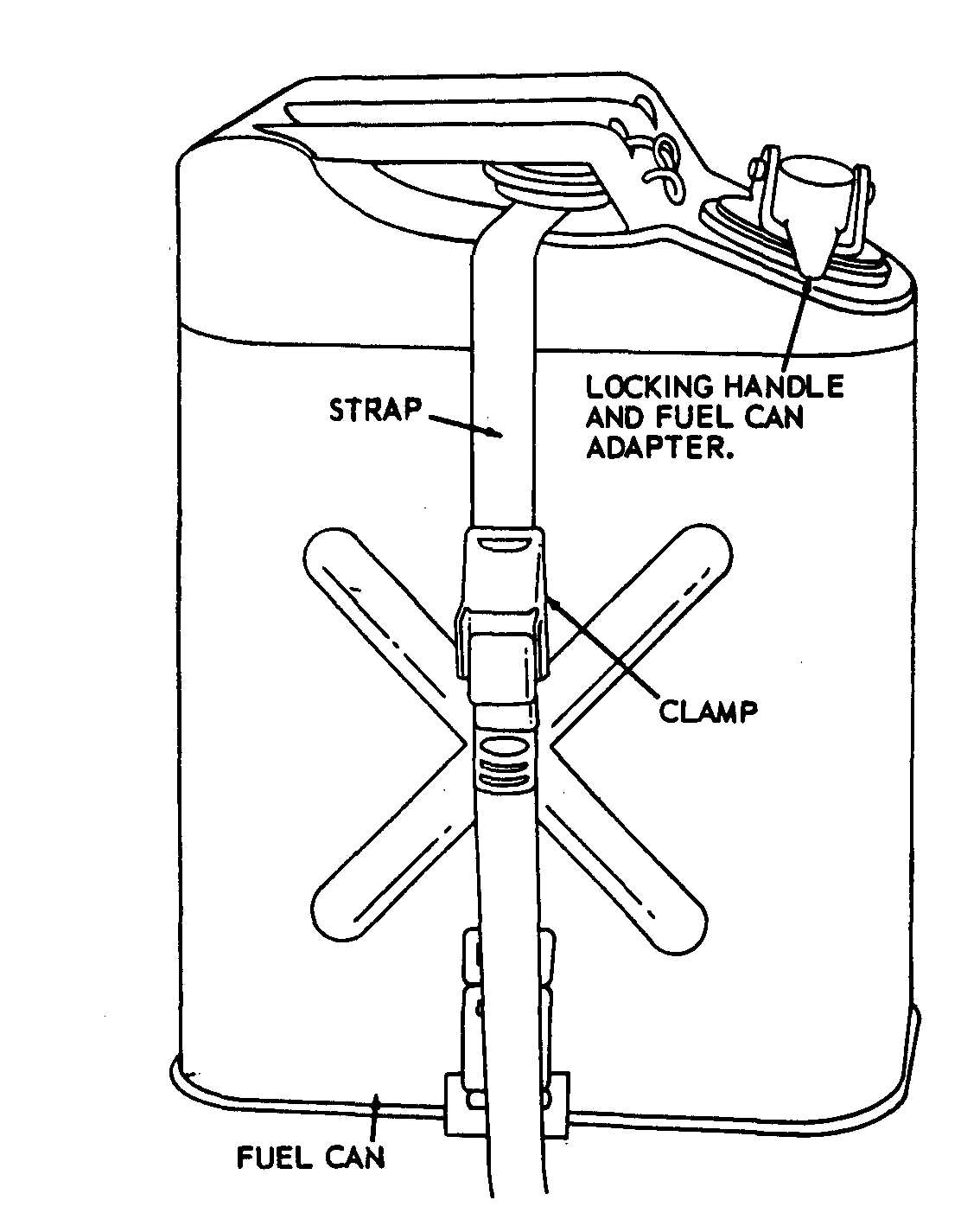

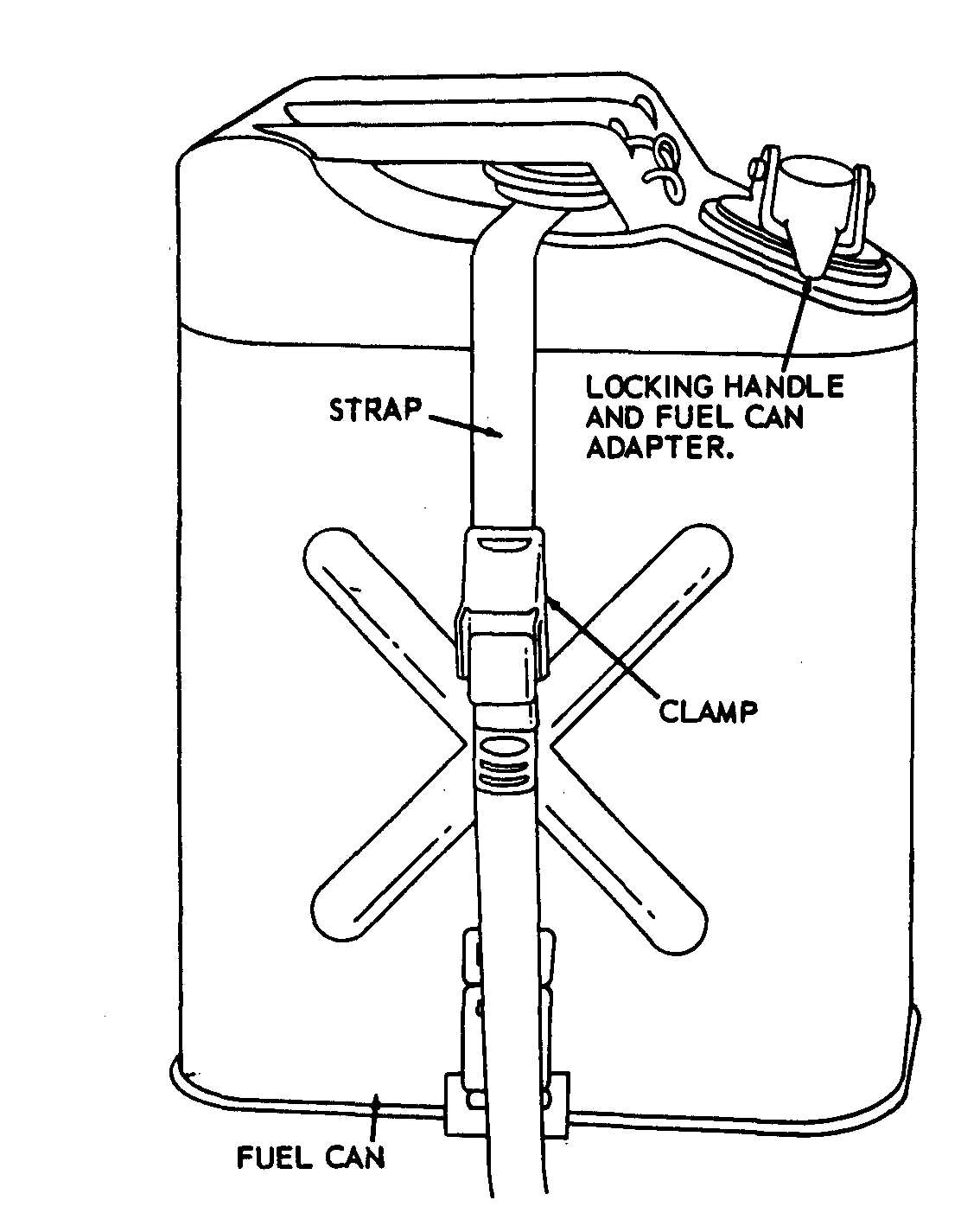

Figure 3-4. Fuel can, removal and installation.

3-12.

Electrical System

a. Inspect the battery cable, hold down frame, starter

cable, and slave receptacle for damage.

b. For replacement, report to organizational

maintenance.

3-13.

Battery

a. Inspection. Inspect battery for cracks and for

proper electrolyte level.

b. Service.

When servicing the battery, do not

smoke or use an open flame in the

vicinity. Batteries generate a highly

explosive gas.

NOTE

The 6TN and 6TL batteries can be mixed or

matched. However, maintenance-free batteries

cannot be mixed or matched with military

batteries. The 6TN and or the 6TL batteries will

perform properly in hot weather as long as

electrolyte levels are carefully monitored. If the

electrolyte expands and causes the level to rise,

some fluid must be removed. If the level becomes

too low due to evaporation, distilled water may be

used to obtain the proper level. A good grade of

drinking water (excluding mineral waters) may be

used if distilled water is not available.

Electrolyte (NSNs 6810-00-249-9354 and

6810-00–843-1640) have a specific gravity of

1.280 and should be used in these batteries. Do

NOT adjust the electrolyte in wet batteries to a

lower specific gravity.

Remove the battery vent caps and fill each cell of the

battery to the proper level with distilled water. The correct

level is 3/8 inch (0.95 cm) above the plates. Install the vent

caps.

c. Utilize slave receptacle to supply external power

for charging batteries and extra cranking power.

3-14. Control Box Assembly

a. Removal.

(1) Open the front of the control box by unlocking

the five fasteners located near the top and at the sides of the

control panel.

(2) For removal of fuse (Model MEP-017A), refer

to figure 3–2.

(3) For removal of the lamps, refer to figure 3-3.

b. CIeaning. Clean the fuses and the lamps with a

clean, lint free cloth.

3-14

Change 8