TM 5-6115-596-14

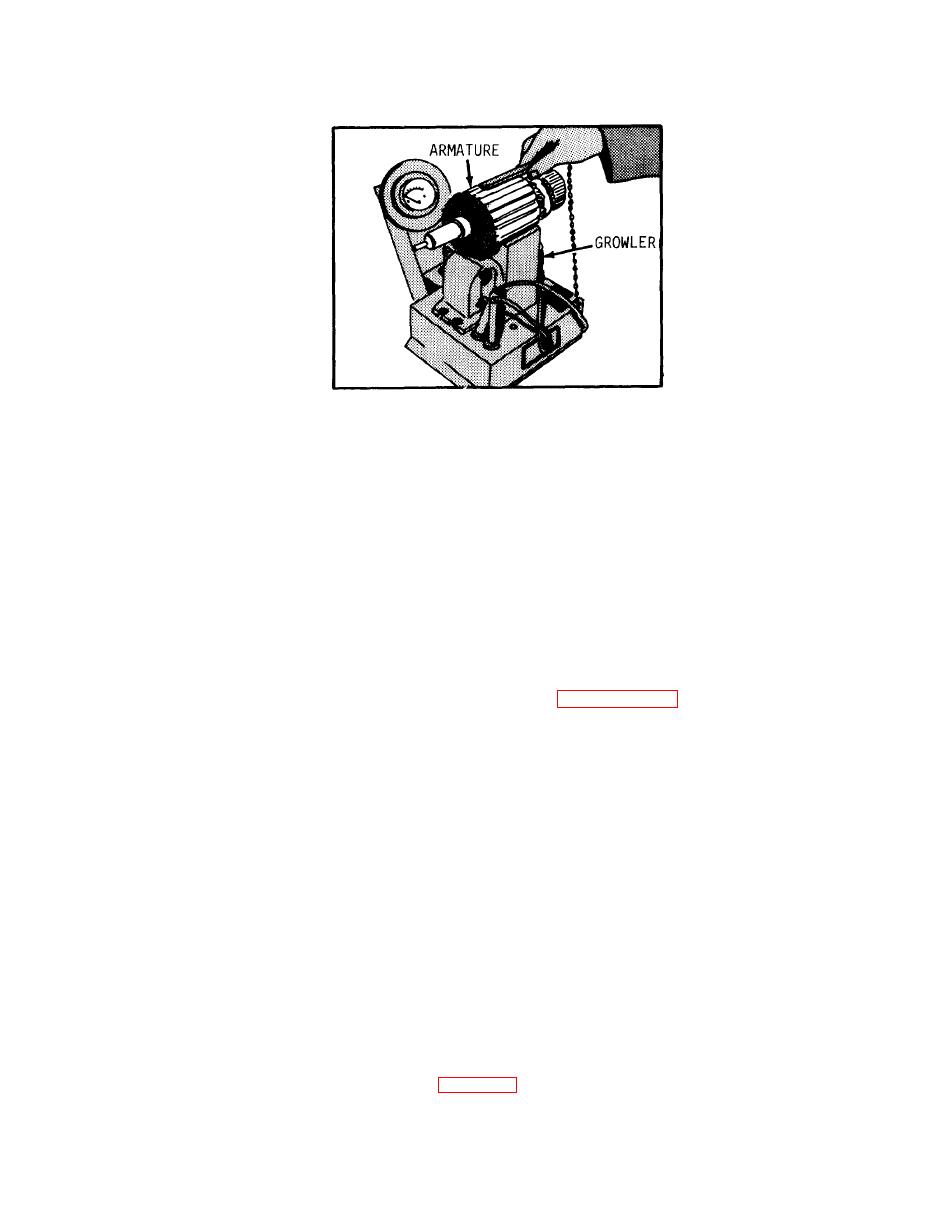

Figure 59.

Testing armature for short circuits

c.

Brushes.

If brushes are worn to lateral wear groove in edge

of brush (maximum wear allowable), replace brushes in sets.

If

brushes are approaching wear groove when generator is received for

repair, replace brushes to extend operation time after repairs before

replacement is again necessary.

d.

Brush Springs.

Check brush springs for distortion and cracks.

Check brush spring tension as shown in figure 5-10.

Spring tension

is between 45 and 54 ounces when spring is in position with a new

brush installed.

Replace springs that are distorted, cracked, or not

within tension tolerances.

e.

Generator Housing Assembly .

(1) Visually inspect generator housing assembly, making certain

that pole shoe attaching screws are tight and staked.

(2) Inspect external insulation of field coils. If insulation

is burned or cracked, or if coils show signs of mechanical damage,

replace entire housing assembly.

(3) To test for short circuits, use same test circuit equipment

used for testing armature (fig. 5-8).

Connect one test lead to

5-31