TM 5-6115-332-14

P-8-614-14

TO 35C2-3-424-1

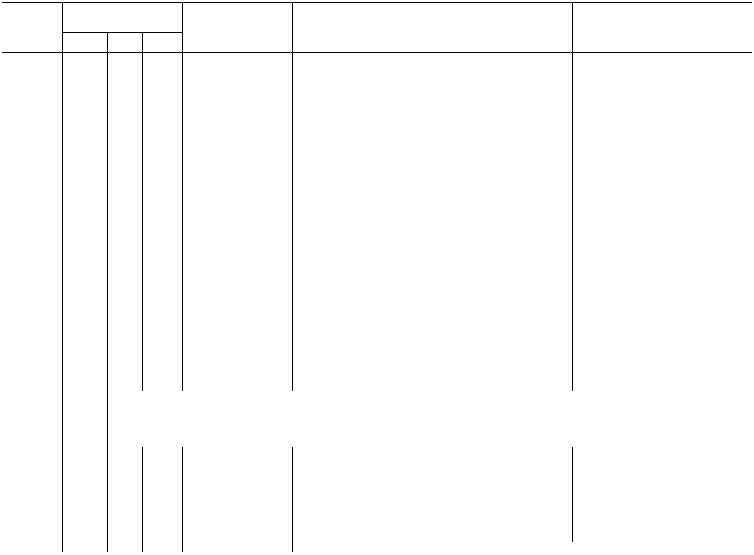

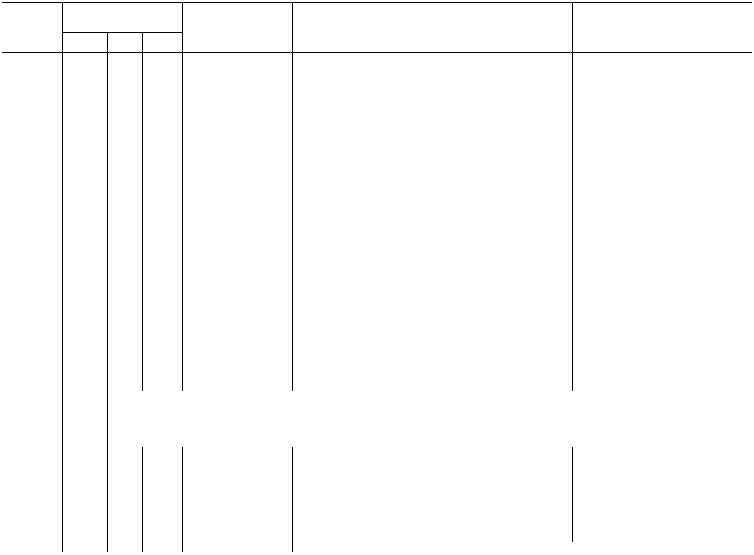

Table 3-2. OPERATOR/CREW PREVENTIVE MAINTENANCE CHECKS AND SERVICES

B-BEFORE OPERATION

A-AFTER OPERATION

D-DURING OPERATION

INTERVAL

ITEM

PROCEDURES

EQUIPMENT IS

ITEM

TO BE

CHECK FOR HAVE REPAIRED

NOT READY/

NO.

B

D

A

INSPECTED

OR ADJUSTED AS NECESSARY

AVAILABLE IF:

1

•

•

Generator Set

a.

Visually inspect the generator set for

Class III oil or Class I

fuel and oil leaks

fuel leak is detected.

•

b.

Check engine oil level. Add od as

necessary.

•

c.

Check for proper ground connection.

Generator is not prop-

erly grounded.

•

d.

.Inspect for loose, damaged, or missing

Any loose, damaged.

parts and unusual wear or deterioration

or missing parts: (i.e.,

Clean unit as necessary.

spark plugs, man-

ifolds, starter, or other

items).

•

e.

Insure load terminal wires are tight-

Loose load terminal

ened

wires.

•

•

f.

Check battery for tight terminals and

Unserviceable or loose

missing parts.

battery terminals and

missing parts.

•

•

g.

Visually inspect all controls for ser-

Loose wire connec-

viceability before starting generator

tions or broken meter

glass.

•

h.

Inspect for cracked or broken welds.

2

Controls and

Instruments shall indicate within speci-

Instruments

fled limits (para 2-1).

•

a. Frequency

60/400 Hz

Fequency cannot be

properly adjusted.

NOTE

Start generator after visual PMCS; insure generator operates as stated in paragraph 2-1.

3-4 Change 10