TM 5-6115-275-14

NAVFAC P-8-615-14

TO 35C2-3-452-1

Do not smoke or use an open flame in

the vicinity when servicing the batteries.

Batteries generate hydrogen, a highly

explosive gas. Failure to observe this

warning may result in serious injury to

personnel.

(1)

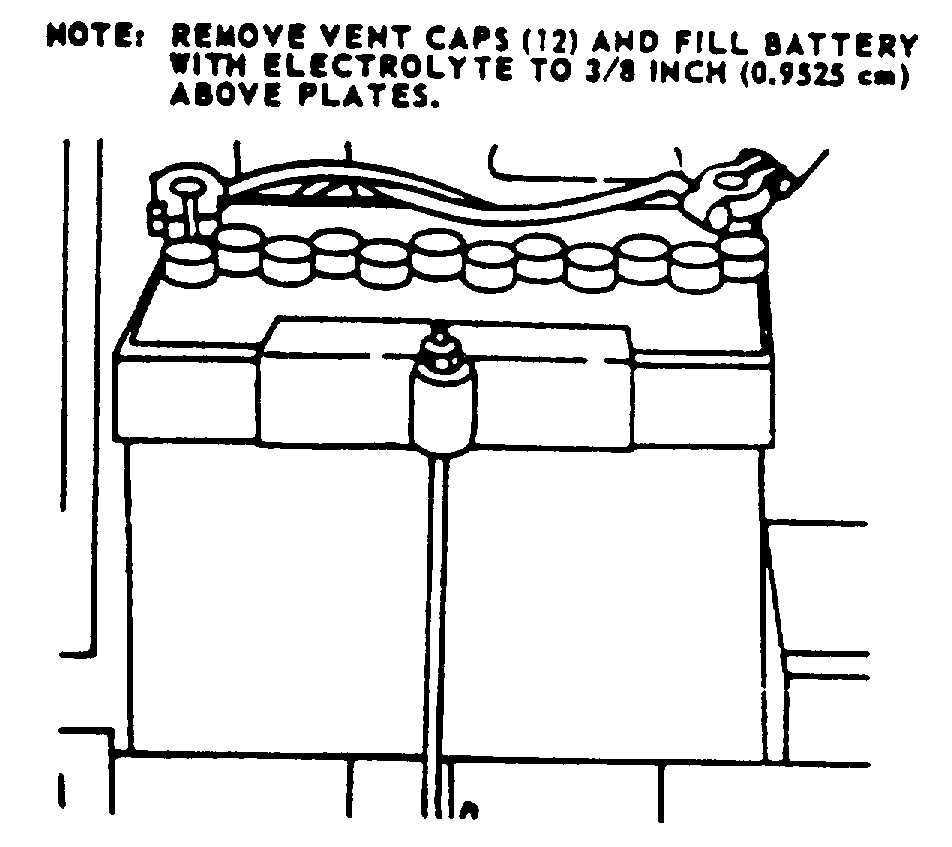

Check the electrolyte for proper level (fig 3-10)

and see that the batteries are properly charged (TM 9-

6140-200-15). The danger of freezing depends on the

specific gravity of the electrolyte.

CAUTION

Water added to a battery will freeze

unless it is mixed by charging. Do

not add water unless the engine is to

be operated immediately afterwards

for at least 1 hour.

(2)

Make sure the battery cap vents are not clogged.

(3)

See that the battery terminal clamps are tight,

clean, and lightly coated with a general purpose grease

to retard corrosion.

(4)

Make sure the Battery Terminal Covers, NSN

5940-00-738-6272, are installed over the battery

terminals before installing cables.

Figure 3-10. Battery servicing.

NOTE

The 6TN and 6TL batteries can be

mixed

or

matched.

However,

maintenance-free batteries cannot be

mixed or matched with military batteries.

The 6TN and or the 6TL batteries will

perform properly in hot weather as long

as

electrolyte

levels

are

carefully

monitored. If the electrolyte expands

and causes the level to rise, some fluid

must be removed. If the level becomes

too low due to evaporation, distilled

water may be used to obtain proper

level. A good grade of drinking water

(excluding mineral waters) may be used

if distilled water is not available.

Electrolyte (NSNs 6810-00-249-

9354 and 6810-00-843-1640) have a

specific gravity of 1.280 and should be

used in these batteries. Do NOT adjust

the electrolyte in wet batteries to a lower

specific gravity.

c.

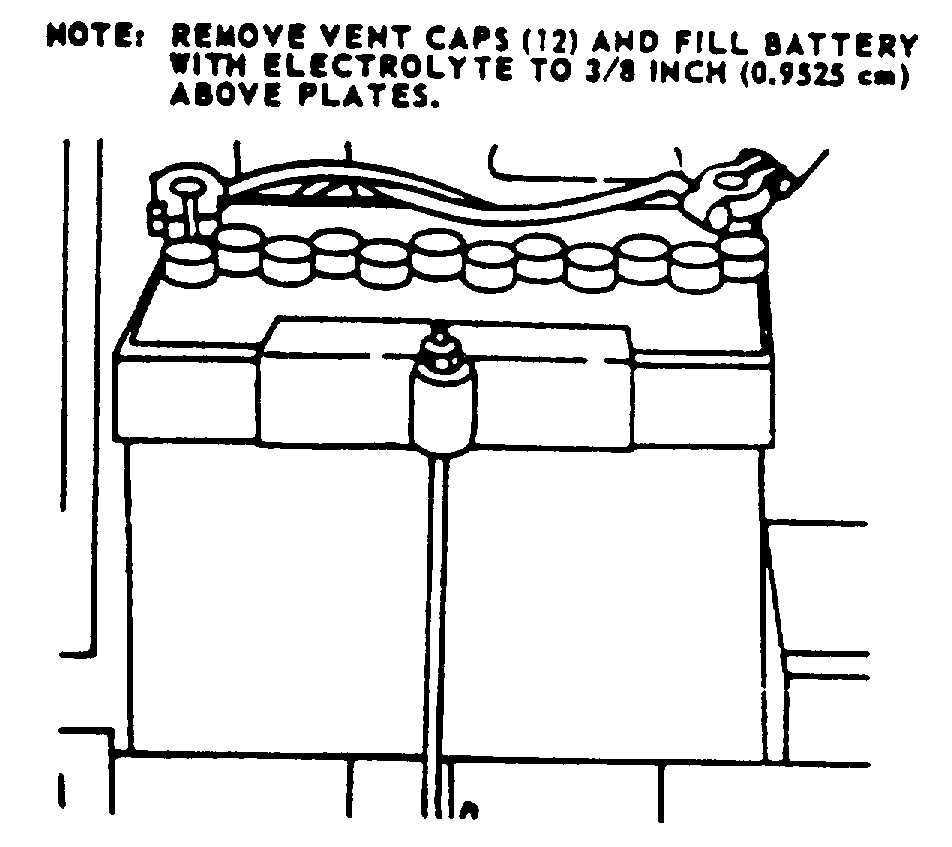

Optional Battery Installation. See Figure 3-11.

Two 12 volt batteries can be installed for optional use in

cold climate where hard starting is prevalent.

Section IX. ELECTRICAL PANELS AND CONTROLS

a.

General.

This

section

contains

operator/crew maintenance instructions for the electrical

components.

b.

Inspection. Inspect the voltage regulator

and

control box components for cracks, breaks, defective

wiring, and wear. For testing and replacement of parts,

refer to organization or field maintenance as allocated by

the Maintenance Allocation Chart (MAC).

Change 9 3-17